WeChat:

+86-189 7322 3283

What’s app::

+86-13630093256

Content Menu

● Why Polybag Packaging Matters

● Xinshunheng’s Capabilities in Polybag Packaging

● Design Considerations for Packaging Lids and Caps

● Case Studies and Applications

● How to Work with Xinshunheng

● FAQs

Xinshunheng Industrial Co., Ltd. stands at the forefront of the packaging (caps and closures) industry, delivering OEM services to foreign brand owners, distributors, and manufacturers worldwide. With a focus on polybag packaging, Xinshunheng leverages advanced materials, precise molding, and rigorous quality control to provide durable, cost-effective, and visually appealing packaging solutions. This article explores why polybag packaging is a strategic choice for international brands and how Xinshunheng Industrial Co., Ltd. can optimize your packaging workflow from design to delivery.

– Polybag packaging offers excellent protection against moisture, dust, and light exposure, preserving product integrity during storage and transit.

– Lightweight and space-efficient, polybag packaging reduces shipping costs and increases pallet density.

– Customizable polybag packaging supports branding through clear windows, imprime designs, and color options.

– Eco-friendly options, such as recyclable polybags and thinner gauge materials, align with sustainability goals.

– Custom design services for polybag packaging, including size, thickness, and material selection to suit product requirements.

– Precision molding and sealing technology tailored for packaging lids and caps in various shapes and sizes.

– Comprehensive quality assurance, including leak tests, tamper-evident features, and material conformity checks.

– Fast prototype-to-production cycles, enabling rapid market testing and scale-up.

– Integrated supply chain management to coordinate raw materials, production, and logistics for polybag packaging orders.

– Polyethylene (PE) and Polypropylene (PP) bags, with options for low-density and high-density formulations for different barrier needs.

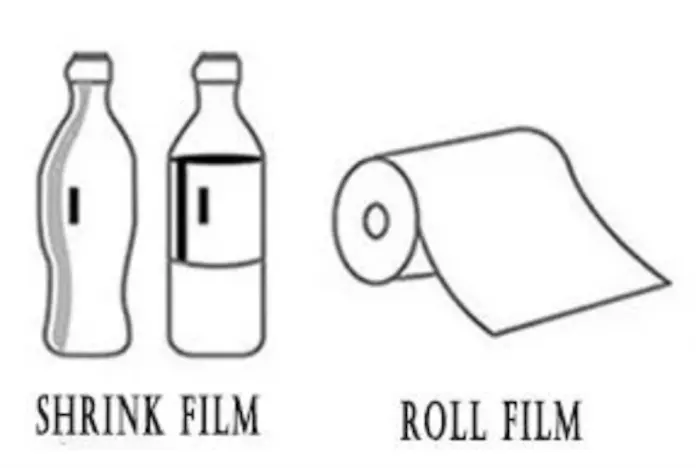

– Coextruded films and metallized laminates for premium presentation and enhanced barrier properties.

– Printed graphics, UV-resistant inks, and heat-seal compatibility for long-lasting branding.

– Barrier properties to protect contents from moisture and oxygen during transit.

– Tamper-evident features embedded in polybag packaging to ensure product integrity.

– Stackability and nesting designs to optimize warehouse space.

– Clear labeling and barcoding compatibility to streamline inventory and QA processes.

– Compatibility with automated filling and capping lines in manufacturing environments.

– Adherence to international standards for packaging materials, including hygiene and safety requirements.

– Documentation packages with material certifications, test reports, and compliance declarations.

– Ongoing supplier audits and process validation to ensure consistent performance of polybag packaging.

– Various bag gauges, sizes, and finish options aligned with product dimensions and branding guidelines.

– Window cutouts, recyclable materials, and resealable closures where appropriate.

– Custom artwork services for logos, slogans, and product information on polybag packaging.

– Flexible MOQs aligned with brand launch timelines.

– Lead times optimized through supplier partnerships and in-house production capabilities.

– Renewable and recyclable materials to support circular economy initiatives.

– Consumer packaged goods (CPG) requiring protective polybag packaging for small components.

– Pharmaceutical and medical devices seeking sterile or tamper-evident polybag packaging.

– Educational kits and electronics accessories that benefit from clear, informative polybag packaging.

– Food and beverage packaging where moisture resistance and safety labeling are critical.

– Adoption of recyclable polybags and formulations that minimize environmental impact.

– Initiatives to reduce material use while maintaining protective performance.

– Partnering with customers to design sustainable packaging solutions that meet regulatory and consumer expectations.

– Continuous improvement programs for material selection, sealing technology, and print capabilities.

– Collaboration with customers on packaging prototypes to refine aesthetics, durability, and cost.

– Investment in automation for consistent quality and scalable production.

– Share product specs, dimensions, and any regulatory compliance requirements.

– Discuss desired polybag packaging attributes such as barrier properties, print quality, and sustainability goals.

– Review artwork, color accuracy, and labeling needs during the pre-production stage.

– Confirm lead times, MOQs, and logistics arrangements to align with market launches.

– What is polybag packaging, and why is it suitable for lids and caps?

Polybag packaging is a flexible film pouch solution that protects products while enabling branding and efficient storage. It is suitable for lids and caps due to its lightweight nature and compatibility with automated handling.

– Can Xinshunheng customize polybag packaging for small components?

Yes, Xinshunhengheng offers custom sizes, thicknesses, materials, and printing to fit specific lid and cap configurations.

– What sustainability options are available for polybag packaging?

Options include recyclable materials, thinner gauges with maintained barrier performance, and inks and laminates with lower environmental impact.

– What certifications can Xinshunheng provide for packaging materials?

Certifications cover material safety, food-contact suitability where applicable, and compliance with international packaging standards.

– How long does a typical polybag packaging project take from design to production?

Lead times vary by complexity and MOQ, but Xinshunhengheng supports rapid prototyping and staged production to meet market timelines.

Hot Tags:Custom Polybag Packaging Solutions,Biodegradable Polybag Packaging Options,Clear Polybag Packaging for Retail Products,Printed Polybag Packaging for Branding,Food-Grade Polybag Packaging Materials, manufacturers, Customized, custom, suppliers, buy, cheap, Quality, Advanced, Durable, in stock, free sample, made in China, price, quotation