WeChat:

+86-189 7322 3283

What’s app::

+86-13630093256

Content Menu

● Understanding Your Packaging Needs

>> Determine the Purpose of the Packaging Bag

>> Consider Environmental and Sustainability Goals

● Evaluating Supplier Qualifications

>> Assess Production Capacity and Capabilities

>> Verify Quality Control Systems

>> Evaluate Customer Service and Support

● Comparing Quotes and Contract Terms

>> Review Contract Details Thoroughly

● Additional Key Criteria for Choosing a Packaging Supplier

>> Choose a Supplier That Designs and Produces

>> Consider Location and Logistics

>> Specialization in Your Industry

>> Corporate Social Responsibility (CSR) Commitment

● Additional Considerations for Packaging Bag Suppliers

>> Innovation and Technology Adoption

>> Flexibility and Customization Options

>> Risk Management and Contingency Planning

● Practical Tips for Working with Packaging Bag Suppliers

>> Establish Clear Specifications

>> Evaluate Total Cost of Ownership

● Building a Long-Term Partnership

>> Maintain Open Communication

>> Continuous Performance Evaluation

● FAQ

>> 1. What factors should I consider when choosing a packaging bag supplier?

>> 2. How important is supplier location?

>> 3. What certifications should a packaging bag supplier have?

>> 4. Can I customize packaging bags with my branding?

>> 5. How do I ensure the supplier maintains quality standards?

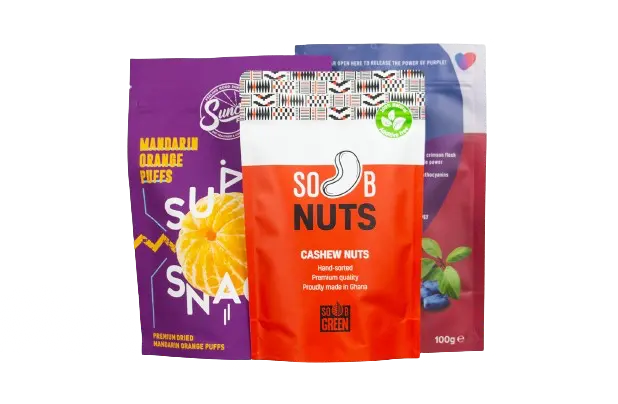

Choosing the right packaging bag supplier is a critical decision that can significantly impact your product’s presentation, protection, and overall brand image. Whether you are in the food industry, electronics, cosmetics, or retail, selecting a supplier that meets your specific needs requires careful consideration of multiple factors. This comprehensive guide will walk you through the essential steps and criteria to help you find the best packaging bag supplier for your business.

Before beginning your search for a supplier, clarify the exact purpose of the packaging bags you need. Packaging bags serve various functions depending on the product type:

– Food products require packaging that complies with food safety standards, ensuring hygiene and freshness.

– Electronics might need anti-static or protective packaging to prevent damage.

– Retail goods often demand visually appealing packaging that supports branding and marketing efforts.

Knowing the application will help you narrow down suppliers who specialize in the materials and certifications relevant to your industry.

Setting a realistic budget is essential. While cost is a major factor, it’s important to balance price with quality. Sometimes, investing more upfront in high-quality packaging can reduce long-term costs related to product damage, returns, or brand reputation damage. Consider all costs, including production, shipping, taxes, and potential customs fees.

With global emphasis on sustainability, many businesses now prefer suppliers offering recyclable, biodegradable, or compostable packaging materials. Choosing a supplier aligned with your environmental values not only supports corporate social responsibility but also appeals to eco-conscious consumers.

A reliable supplier should have sufficient production capacity to meet your order volumes and deadlines. This includes:

– Advanced production equipment

– Multiple production lines

– Skilled workforce

A supplier with strong manufacturing capabilities can handle order fluctuations and ensure timely delivery, which is crucial for your supply chain stability.

Quality is paramount in packaging. Check if the supplier has certifications such as ISO, BRC, or FDA compliance, depending on your industry. Request product samples and, if possible, visit the factory to inspect their quality control processes firsthand. A robust quality management system reduces risks of defects and recalls.

Good communication and responsive customer service improve cooperation efficiency. Your supplier should offer technical support, timely responses, and after-sales service. This partnership approach helps resolve issues quickly and supports continuous improvement.

Obtain detailed quotations from several suppliers. Don’t just compare prices-consider shipping costs, minimum order quantities, lead times, and payment terms. Extremely low prices can be a red flag for compromised quality or hidden fees.

Before signing any contract, carefully examine terms related to delivery schedules, payment methods, liability clauses, and penalties for breaches. Consulting a legal advisor can help protect your interests and ensure clarity in the business relationship.

Selecting a supplier who manages both design and production simplifies the process. It allows better control over quality, reduces lead times, and facilitates customization. Suppliers with in-house factories offer greater flexibility to adapt to changes and improve transparency.

The proximity of the supplier’s production facilities to your distribution centers affects delivery speed and costs. Local or regional suppliers can reduce customs tariffs and shipping delays. Also, inquire about the supplier’s logistics capabilities, such as warehousing and transportation, which can streamline your supply chain and reduce environmental impact.

Suppliers specializing in your sector-whether luxury goods, food packaging, or industrial products-understand specific requirements and standards. Their expertise can save time and ensure packaging aligns with your brand’s image and customer expectations.

A supplier’s CSR policies reflect their dedication to ethical, social, and environmental standards. Partnering with a supplier who shares your values enhances your brand’s credibility and supports sustainable development goals.

In today’s fast-paced market, innovation plays a crucial role in packaging solutions. Suppliers who invest in the latest technology and research can offer advanced packaging options such as smart packaging, tamper-evident features, and improved barrier properties. These innovations can enhance product safety, extend shelf life, and provide added value to your customers.

For example, smart packaging embedded with QR codes or NFC chips can engage consumers with product information or authenticity verification. Tamper-evident seals increase consumer trust by ensuring the product has not been altered.

Beyond basic customization, consider suppliers who offer flexible production runs and the ability to quickly adapt to design changes or new product launches. This agility can be a significant advantage in responding to market trends and consumer preferences. Suppliers that can handle small batch orders or rapid prototyping enable you to test new packaging concepts without large upfront commitments.

Transparency in the supply chain is increasingly important for businesses aiming to ensure ethical sourcing and sustainability. Suppliers who provide clear information about their raw materials, labor practices, and environmental impact help build trust and align with corporate social responsibility goals. This transparency can also help you meet regulatory requirements and consumer demand for ethical products.

Evaluate whether the supplier has robust risk management strategies in place, including contingency plans for supply disruptions, quality issues, or regulatory changes. A proactive supplier can minimize potential risks to your business operations. For instance, suppliers with multiple manufacturing sites or diversified raw material sources can better withstand disruptions.

Provide detailed specifications for your packaging needs, including dimensions, materials, printing requirements, and performance standards. Clear communication reduces misunderstandings and ensures the final product meets your expectations. Using technical drawings or prototypes can aid in this process.

Developing a collaborative relationship with your supplier fosters mutual understanding and long-term success. Regular meetings, feedback sessions, and joint problem-solving can improve product quality and innovation. A strong partnership also facilitates flexibility when urgent changes or challenges arise.

Stay informed about industry trends, new materials, and regulatory changes. Sharing this knowledge with your supplier can help you both stay competitive and compliant. For example, trends toward sustainable materials or minimalist packaging design may influence your packaging strategy.

Consider all costs associated with packaging, including storage, handling, transportation, and disposal. Sometimes a higher upfront cost is justified by savings in other areas, such as reduced waste, easier logistics, or enhanced brand perception.

Successful partnerships rely on transparent and ongoing communication. Sharing market trends, feedback, and future plans helps both parties optimize packaging solutions and adapt to changing needs. This openness also builds trust and prevents misunderstandings.

Regularly assess your supplier’s performance regarding quality, delivery, and service. This ensures that the partnership remains beneficial and allows you to make adjustments or explore new options proactively. Setting key performance indicators (KPIs) can help measure success objectively.

Choosing the best packaging bag supplier is a multifaceted process involving a clear understanding of your packaging needs, thorough evaluation of supplier capabilities, and careful comparison of costs and contract terms. Prioritizing quality, reliability, environmental responsibility, and strong communication will help you establish a fruitful long-term partnership. By following the guidelines outlined in this article, you can confidently select a packaging bag supplier that supports your business growth and brand success.

Ready to elevate your product packaging? Contact us today to find the perfect packaging bag supplier tailored to your business needs!

Consider your product’s packaging purpose, budget, material requirements, supplier’s production capacity, quality control, certifications, customer service, and sustainability practices.

Supplier proximity affects delivery times, shipping costs, and customs duties. Choosing a supplier near your distribution centers can improve efficiency and reduce expenses.

Look for industry-specific certifications such as ISO, BRC, FDA compliance, or sustainability certifications to ensure quality and regulatory compliance.

Many suppliers offer customization options including logos, colors, and special finishes. Ensure the supplier has design capabilities and experience with branding.

Request samples, visit manufacturing facilities if possible, verify certifications, and establish clear quality control requirements in the contract.

Hot Tags: Packaging Bag Supplier, Custom Packaging Bags, Flexible Packaging Supplier, Packaging Pouch Manufacturer, Wholesale Packaging Bags, Printed Packaging Bags, Resealable Packaging Bags, Food Packaging Supplier, Eco-Friendly Packaging, Bulk Packaging Supplier