WeChat:

+86-189 7322 3283

What’s app::

+86-13630093256

Content Menu

● Understanding Frozen Delivery Packaging

>> Types of Materials Used in Frozen Delivery Packaging

>> Benefits of Frozen Delivery Packaging for Businesses

● Best Practices for Shipping Frozen Products

>> 2. Use Appropriate Packaging

>> 3. Labeling and Handling Instructions

>> 4. Choose Reliable Carriers

>> 5. Monitor Temperature During Transit

● Environmental Impact of Frozen Delivery Packaging

>> 1. What materials are commonly used in frozen delivery packaging?

>> 2. How does frozen delivery packaging benefit businesses?

>> 3. What are the best practices for shipping frozen products?

>> 4. What is the environmental impact of frozen delivery packaging?

>> 5. How can businesses adopt more sustainable packaging solutions?

In today’s fast-paced world, the demand for frozen delivery packaging has surged, driven by the need for efficient and reliable transportation of perishable goods. Xinshunheng Industrial Co., Ltd. stands at the forefront of this industry, providing innovative OEM solutions for businesses looking to maintain the integrity of their frozen products during transit. This article delves into the various aspects of frozen delivery packaging, including materials used, benefits for businesses, best practices for shipping, and the environmental impact of packaging choices.

Frozen delivery packaging refers to specialized packaging solutions designed to keep food and other perishable items at low temperatures during transportation. This type of packaging is crucial for maintaining the quality and safety of products such as frozen foods, pharmaceuticals, and other temperature-sensitive items.

1. Expanded Polystyrene (EPS) Foam: Known for its excellent insulation properties, EPS foam is lightweight and cost-effective, making it a popular choice for shipping frozen goods. However, its environmental impact due to non-biodegradability is a growing concern.

2. Polyurethane Foam (PU): This material offers superior thermal retention and is often used in rigid thermal boxes for long-haul shipping. While effective, PU foam is also not recyclable.

3. Reflective Foil Insulation: Often used in combination with other materials, reflective foil helps to minimize heat transfer, keeping products frozen for extended periods.

4. Biodegradable Materials: As sustainability becomes a priority, many companies are exploring biodegradable options such as plant-based plastics and recycled paper products. These materials help reduce the environmental footprint of frozen delivery packaging.

5. Gel Packs and Dry Ice: These cooling agents are essential for maintaining low temperatures during transit. Gel packs are reusable and can be made from non-toxic materials, while dry ice is effective for ultra-cold shipments.

1. Extended Shelf Life: Proper frozen delivery packaging significantly extends the shelf life of perishable products, allowing businesses to manage inventory more effectively and reduce waste.

2. Cost Efficiency: By minimizing spoilage and waste, businesses can save on costs associated with product loss. Additionally, efficient packaging can reduce shipping expenses by optimizing space and weight.

3. Consumer Satisfaction: High-quality packaging ensures that products arrive in optimal condition, enhancing customer satisfaction and loyalty. This is particularly important in the competitive frozen food market.

4. Regulatory Compliance: Many industries, including food and pharmaceuticals, are subject to strict regulations regarding temperature control. Effective frozen delivery packaging helps businesses comply with these regulations, avoiding potential fines and ensuring product safety.

5. Sustainability: As consumers become more environmentally conscious, businesses that adopt sustainable packaging solutions can enhance their brand image and appeal to eco-minded customers.

To ensure the integrity of frozen products during shipping, businesses should adhere to the following best practices:

Before shipping, products should be pre-frozen to maintain their quality and prevent condensation during transit. This step is crucial for items that are sensitive to temperature fluctuations.

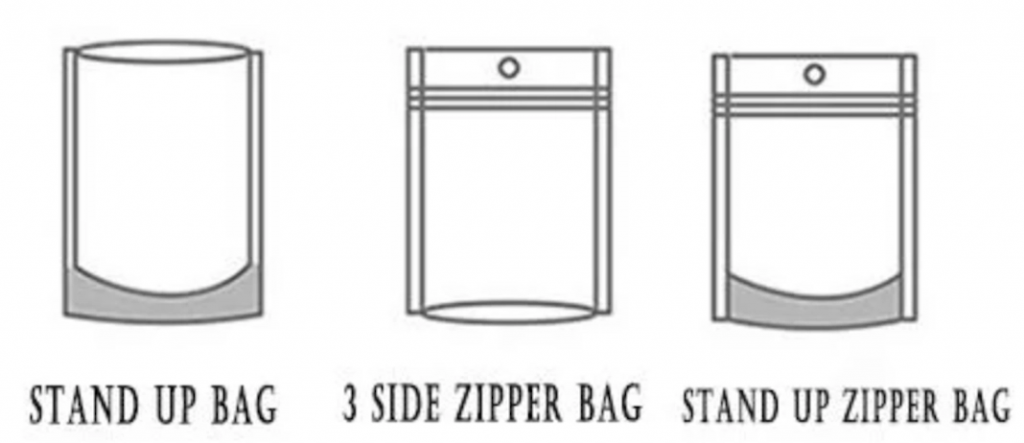

Selecting the right packaging materials is essential. Insulated containers, watertight plastic bags, and cushioning materials should be used to protect products from moisture and physical damage.

Packages should be clearly labeled with handling instructions to ensure that all personnel involved in the shipping process understand the importance of maintaining temperature control.

Partnering with reputable carriers that specialize in temperature-controlled logistics is vital. These carriers should have the necessary equipment and experience to handle frozen goods effectively.

Utilizing temperature monitoring devices can help track the conditions of frozen products throughout the shipping process, ensuring that they remain within the required temperature range.

While frozen delivery packaging plays a crucial role in preserving product quality, it also poses environmental challenges. The use of non-biodegradable materials, such as traditional plastics and polystyrene, contributes to pollution and waste. However, the industry is making strides toward sustainability by adopting eco-friendly packaging solutions.

1. Recyclable Materials: Many companies are now using recyclable materials, such as polyethylene terephthalate (PET), which can be repurposed after use, reducing landfill waste.

2. Compostable Packaging: Innovations in compostable materials are providing alternatives that break down naturally, minimizing environmental impact.

3. Reduced Packaging: Companies are exploring ways to reduce the amount of packaging used without compromising product safety, such as optimizing box sizes and using thinner materials.

4. Sustainable Production Practices: Implementing energy-efficient manufacturing processes can further reduce the carbon footprint associated with frozen delivery packaging.

Frozen delivery packaging is an essential component of the cold chain, ensuring that perishable products reach consumers in optimal condition. Xinshunheng Industrial Co., Ltd. is committed to providing innovative and sustainable packaging solutions that meet the needs of businesses while addressing environmental concerns. By understanding the materials used, the benefits of effective packaging, and best practices for shipping, companies can enhance their operations and contribute to a more sustainable future.

Common materials include EPS foam, PU foam, reflective foil insulation, biodegradable materials, gel packs, and dry ice.

It extends shelf life, reduces costs, enhances consumer satisfaction, ensures regulatory compliance, and supports sustainability efforts.

Best practices include pre-freezing products, using appropriate packaging, labeling, choosing reliable carriers, and monitoring temperature during transit.

Traditional packaging materials can contribute to pollution and waste, but sustainable alternatives are being developed to minimize environmental impact.

Businesses can use recyclable and compostable materials, reduce packaging waste, and implement energy-efficient production practices.

Hot Tags:Insulated Packaging For Frozen Food Delivery,Eco-Friendly Frozen Food Packaging Solutions,Custom Frozen Food Delivery Boxes,Thermal Packaging For Frozen Meals,Frozen Food Packaging Suppliers, manufacturers, Customized, custom, suppliers, buy, cheap, Quality, Advanced, Durable, in stock, free sample, made in China, price, quotation