WeChat:

+86-189 7322 3283

What’s app::

+86-13630093256

Content Menu

● What Are Biodegradable Stand Up Pouches?

● Why Brands Choose Biodegradable Stand Up Pouches

● Xinshunheng Industrial Co., Ltd.: Your OEM Partner

● Material Considerations for Biodegradable Stand Up Pouches

● Design and Engineering Aspects

● Quality Assurance and Compliance

● Practical Applications for Biodegradable Stand Up Pouches

● Why OEM with Xinshunheng Industrial Co., Ltd.?

● Sustainability Considerations and Consumer Perception

● Case Study: What a Successful OEM Partnership Looks Like

● Guidance for Selecting an OEM Partner

● The Future of Biodegradable Stand Up Pouches

● FAQ

Xinshunheng Industrial Co., Ltd. stands at the forefront of packaging innovation, proudly offering OEM solutions for biodegradable stand up pouches that meet the evolving demands of foreign brand owners, wholesalers, and manufacturers. As a China-based packaging cap and pouch expert, we empower our partners with high-performance, eco-friendly packaging options that combine durability, barrier properties, and sustainability. This article explores why biodegradable stand up pouches are a smart choice for modern brands, how Xinshunheng Industrial Co., Ltd. delivers value, and what your company should consider when selecting an OEM partner.

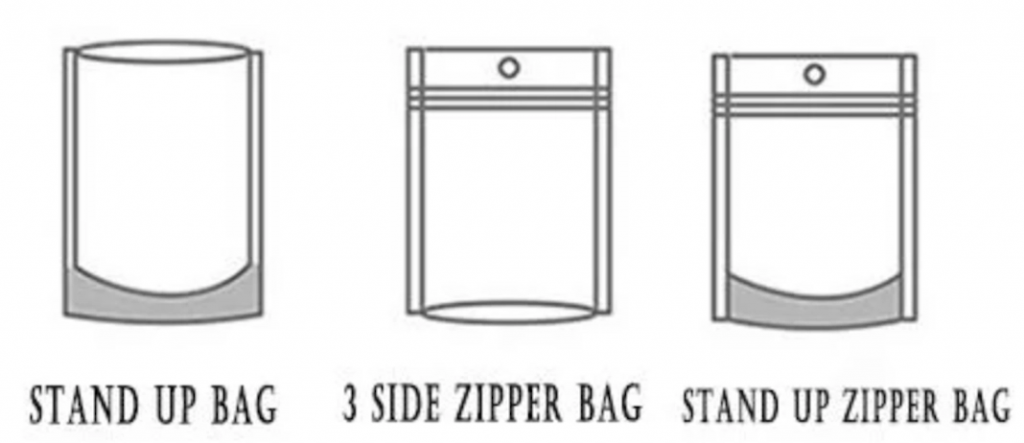

Biodegradable stand up pouches are flexible packaging solutions designed to stand upright on shelves, with a gusseted bottom and resealable or easy-tear features. When manufactured with biodegradable materials, these pouches decompose more rapidly under appropriate industrial or home-composting conditions, reducing long-term environmental impact. They are ideal for a wide range of products, including snacks, coffee, pet foods, dried fruits, and granola, where shelf appeal and product protection are critical.

– Cost-effective shelf presence: Eye-catching layouts and clear branding on stand-up pouches attract consumer attention.

– Enhanced product protection: Barrier properties safeguard against moisture, oxygen, and light, extending shelf life.

– Convenience and consumer experience: Resalable zippers, tear Notches, and easy-open features improve usability.

– Sustainability alignment: Biodegradable materials help brands meet ESG goals and respond to consumer demand for eco-friendly packaging.

– Regulatory readiness: Many regions are tightening regulations around single-use plastics, making biodegradable options increasingly attractive.

– End-to-end OEM capabilities: From material selection and barrier testing to printing, lamination, bag formation, and finished goods QA.

– Customization flexibility: IML, heat-seal options, zippers, tear notches, windows, and multiple sizes to fit diverse product lines.

– Global quality standards: Strict supplier audits, traceability, and consistent performance across batches.

– Short lead times: Streamlined project management and efficient manufacturing processes for international brands.

– Responsible sourcing: Commitment to sustainable materials and responsible supply chain practices.

– Biopolymers: Polylactic acid (PLA), polyhydroxyalkanoates (PHA), and bio-based polyethylene variants that are designed to biodegrade under composting conditions.

– Barrier layers: EVOH or PVDC-coated films for oxygen/moisture barrier, combined with biodegradable substrates to maintain product integrity.

– Printing compatibility: Food-grade inks and coatings that meet regulatory requirements without compromising biodegradability.

– End-of-life guidance: Clear disposal instructions to help consumers participate in proper composting or recycling streams where available.

– Size and capacity: Determine the target product weight and package dimensions to optimize material use and cost.

– Gusset configuration: Side or bottom gussets to achieve a stable standing position and maximize display surface.

– Closure mechanisms: Zippers, resealable closures, or tear notches to balance convenience with material integrity.

– Visual appeal: High-quality printing (CMYK or spot colors), matte or gloss finishes, and transparent windows that do not hinder biodegradability.

– Material testing: Barrier integrity, seal strength, and migration testing to ensure compliance with food-contact regulations.

– Print quality: Colorfastness, registration, and abrasion resistance under typical shelf conditions.

– Environmental compliance: Documentation for certifications such as compostability, biodegradability, and recyclability where applicable.

– Supplier management: Ongoing audits and control plans to ensure consistent performance across production runs.

– Snack foods: Easy-to-store, appealing packaging that preserves freshness.

– Coffee and tea: Aromatic containment and freshness protection with barrier layers.

– Pet foods: Allergen-conscious and portion-controlled packaging.

– Health foods and supplements: Tamper-evident options and precise dosing indications.

– Dry goods: Grains, nuts, seeds, and dried fruits needing extended shelf life.

– First-mover advantage: Access to cutting-edge biodegradable materials and packaging technologies.

– Custom branding: High-resolution printing and personalized design capabilities to strengthen brand identity.

– Regulatory support: Guidance on labeling, allergen declarations, and country-specific packaging standards.

– Supply chain resilience: Flexible manufacturing and capacity planning to meet fluctuating demand.

– Consumer awareness: Biodegradable stand up pouches align with growing consumer demand for eco-friendly packaging.

– Life cycle thinking: Assess the full environmental impact, including production, use, and end-of-life options.

– Market differentiation: Distinctive design, clear sustainability messaging, and reliable performance can boost brand loyalty.

A foreign brand partner collaborated with Xinshunheng Industrial Co., Ltd. to transition their rigid plastic stand-up pouches to biodegradable stand up pouches. The project involved material trials, barrier optimization, and a complete packaging redesign. The result was a visually compelling, cost-efficient solution that maintained product freshness and reduced the client’s environmental footprint. The brand saw improved consumer engagement, a smoother regulatory path in target markets, and a measurable reduction in plastic usage.

– Material transparency: Insist on full material composition disclosures and third-party testing results.

– Printing and finishing capabilities: Ensure your partner can reproduce your branding consistently across batches.

– Regulatory expertise: Choose a partner with experience navigating food-contact and compostability standards in your target markets.

– Scalability: Confirm the ability to scale production without sacrificing quality or lead times.

– Collaboration model: Look for a partner that treats your brand as a co-creation project, offering proactive design and optimization support.

– Requirement gathering: Align on product, size, material, print design, and packaging specs.

– Material selection and sampling: Evaluate biodegradable substrates and barrier films.

– Prototype development: Create sample pouches for functional testing and visual assessment.

– Validation testing: Conduct seal integrity, barrier performance, and shelf-life tests.

– Pilot production: Run a small batch to verify consistency and quality.

– Full-scale production: Ramp up to meet demand with ongoing QC checks.

– Packaging and ordering: Finalize packing configurations, labeling, and logistics.

As global demand for sustainable packaging continues to rise, biodegradable stand up pouches will play a central role in helping brands meet environmental goals while maintaining product integrity and consumer appeal. Xinshunheng Industrial Co., Ltd. remains committed to advancing material science, design innovation, and manufacturing excellence to support brands around the world.

Q1: What makes biodegradable stand up pouches suitable for my product?

A1: They offer strong barrier protection, stand-up stability on shelves, and a reduced environmental impact compared with traditional plastics, especially when paired with compostable materials and responsible disposal guidance.

Q2: Can Xinshunheng Industrial Co., Ltd. customize biodegradable stand up pouches to my brand?

A2: Yes. We provide full OEM customization including size, gusset style, closures, printing, and branding to match your specifications.

Q3: Are biodegradable stand up pouches compliant with food-contact regulations?

A3: We work with food-grade materials and conduct relevant testing to ensure compliance with target markets’ regulations and provide documentation to support claims.

Q4: What is the typical lead time for a stand up pouch project?

A4: Lead times depend on material selection and customization; our team optimizes the process for efficiency, from prototyping to full-scale production.

Q5: How do you ensure consistent quality across batches?

A5: We implement rigorous QC protocols, supplier audits, and batch testing, along with continuous improvement practices to maintain uniform performance.

Hot Tags:Compostable Stand Up Pouches,Eco Friendly Stand Up Pouches,Recyclable Stand Up Pouches,Sustainable Packaging Pouches,Biodegradable Zip Lock Pouches, manufacturers, Customized, custom, suppliers, buy, cheap, Quality, Advanced, Durable, in stock, free sample, made in China, price, quotation