WeChat:

+86-189 7322 3283

What’s app::

+86-13630093256

Laminated rolls are essential materials in the packaging industry, widely used by brands, wholesalers, and manufacturers to provide durable and attractive packaging solutions. At wl-packaging.com, we specialize in manufacturing high-grade laminated rolls tailored to meet diverse packaging needs with OEM services that guarantee quality, innovation, and customization.

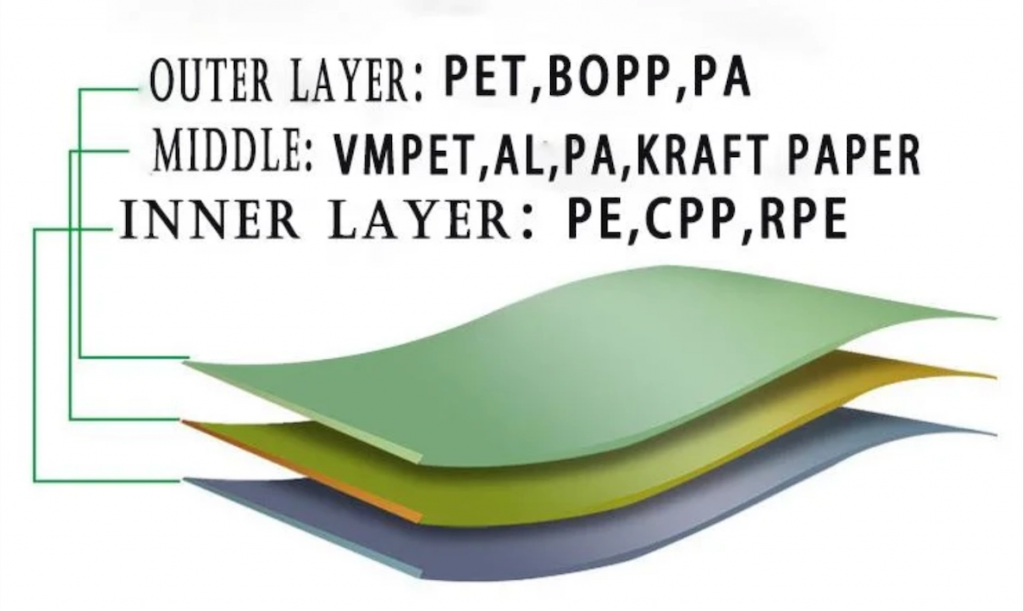

Laminated rolls consist of multiple layers of film, bonded together to combine properties such as strength, flexibility, and barrier protection. These rolls enhance packaging functionality and appeal by improving durability and resistance to moisture, oxygen, and light.

– Multi-layer construction for superior barrier properties

– Lightweight yet robust for packaging efficiency

– Customizable thickness and materials depending on product requirements

– Excellent printability for high-quality branding

Utilizing laminated rolls allows companies to ensure product safety and extend shelf life, making them indispensable in various markets including food, pharmaceuticals, and consumer goods.

At wl-packaging.com, our focus is on delivering premium laminated rolls with outstanding OEM services. We cater to packaging brands and manufacturers worldwide, providing solutions that enable product differentiation and operational efficiency.

– State-of-the-art manufacturing technology ensuring consistent quality

– Flexible order volumes suitable for small to large-scale production

– Tailored material selections to match client-specific applications

– Quick turnaround and reliable delivery schedules

– Expert customer support from consultation to after-sales service

Our commitment to excellence and customization places wl-packaging.com at the forefront as a trusted supplier of laminated rolls internationally.

The versatility of laminated rolls makes them suitable for a wide range of packaging applications. Here are some common uses:

Laminated rolls protect food products by extending freshness and preventing contamination. Their barrier properties ensure moisture and oxygen do not compromise product integrity.

Safety and hygiene standards are critical. Laminated rolls offer secure and tamper-evident packaging capable of preserving medicine quality.

From cosmetics to electronics, laminated rolls provide a sleek finish and durable protection, enhancing product presentation and customer appeal.

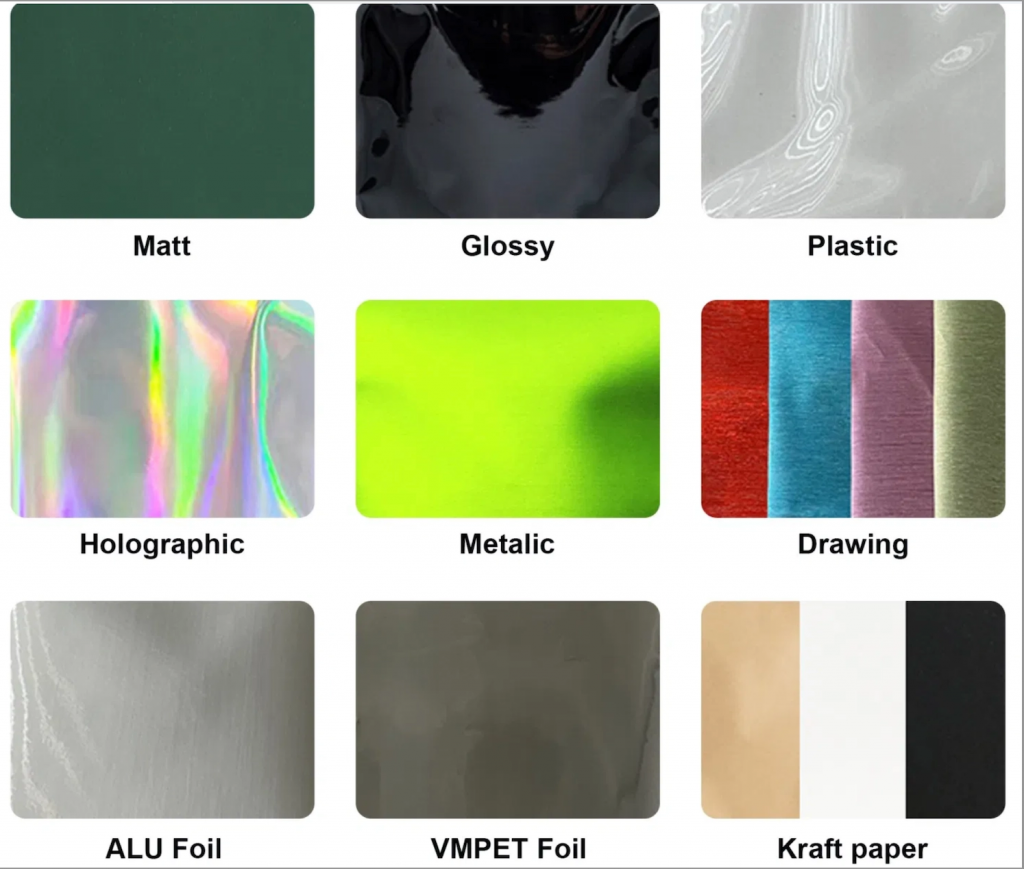

Choosing the appropriate laminated rolls depends on multiple factors including product type, shelf life requirements, and environmental conditions.

– Barrier requirements: moisture, oxygen, UV protection

– Material compatibility for product safety

– Thickness and mechanical strength

– Printing and finishing capabilities

Our technical team at wl-packaging.com assists clients in selecting optimal laminated roll specifications to ensure packaging success and brand integrity.

Sustainability is a key concern in packaging. wl-packaging.com invests in eco-friendly laminated roll solutions.

– Use of recyclable materials and solvent-free adhesives

– Development of biodegradable laminates

– Reduction of material waste through precision manufacturing

These initiatives align with global efforts to reduce environmental impact while providing high-performance packaging options.

Laminated rolls typically combine PET, PE, BOPP, and aluminum foil layers to balance strength and barrier properties.

Yes, at wl-packaging.com, custom widths, lengths, and material combinations are available to suit any packaging requirement.

By providing moisture, oxygen, and UV barriers, laminated rolls prevent spoilage and degradation of packaged goods.

Absolutely. They meet strict food safety standards and protect against contamination and external elements.

Lead times vary by order size and specification, but wl-packaging.com ensures timely production and delivery aligned with client schedules.

For reliable, customizable, and high-quality laminated rolls, wl-packaging.com stands out as the top choice for OEM packaging solutions. Our expertise and advanced manufacturing capabilities satisfy diverse packaging needs, making us a trusted partner for global brands and manufacturers seeking excellence in laminated roll products.

Hot Tags:Custom Laminated Rolls Supplier,Food Grade Laminated Rolls,High Quality Laminated Film Rolls,Laminated Packaging Material Rolls,Flexible Laminated Roll Stock,manufacturers, Customized, custom, suppliers, buy, cheap, Quality, Advanced, Durable, in stock, free sample, made in China, price, quotation